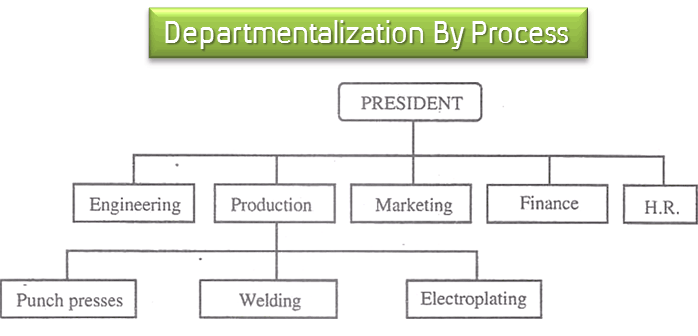

Departmentalization by the process is logical when the machinery or equipment used requires special skill for operating, or is of a large capacity which eliminates organizational dividing, or has technical facilities which strongly suggest a concentrated location.

Economic and technological considerations are the foremost reasons for the adoption of process Departmentalization.

It is most commonly found in production and frequently at operative levels. Using a process as a guide, there are three basic patterns available:

- serial,

- parallel, and

- unit assembly.

The pattern followed will determine, in part, the organizational units adopted. In few instances arts any of these patterns used in pure form. More commonly, part of the work is processed under one pattern, part under another, and so forth.

Under the serial pattern, work moves through a single channel or assembly line and progresses step by step to completion as it `presents various workstations.

This arrangement permits an employee to be highly specialized by an individual work process and usually requires a brief breaking-in time for the attainment of satisfactory output.

However, the “cycle time”, or total elapsed time from the beginning to the ending of J unit of work, may be short, and there is also the possibility of reduced employee work interest under the serial arrangement.

Advantages of Departmentalization by the process

- Achieves economic advantage,

- Uses specialized technology,

- Utilizes special skills,

- Simplifies training.

Disadvantages of Departmentalization by the process

- Co-ordination of departments is difficult,

- Responsibility for profit is at the top,

- Is unsuitable for developing general managers.

Simultaneous handling is one way of expressing the unit assembly arrangement. Different employees perform different work steps on a given amount of work at the same time.

To illustrate, the work to be done is divided among employees A, B, and C.

Simultaneously, employee A performs one particular operation on a batch of work,

B operates on his batch, and likewise C on her batch of work.

At appropriate times the different batches of work are shifted among the employees for completion of the total job.