Learn how to use benchmarking to increase a business’s potential with the secret tool for surpassing industry giants in quality and performance.

What is Benchmarking?

Benchmarking is a developed concept in the field of TQM and is used as an increasingly popular tool for improving product quality and business performance. It is used comprehensively by both manufacturing and service organizations.

Essence of Benchmarking

The essence of benchmarking is the process of borrowing ideas and adapting them to gain competitive advantages inside and outside the organization.

Large companies like Xerox, AT&T, Motorola, Ford, and Toyota are using benchmarking as a very effective tool to ensure TQM in their organizations, customer satisfaction, and increased productivity. Now, you may ask how we can define or describe benchmarking. Several people have defined benchmarking in different ways.

However, the common theme in their definitions is that it is a tool to compare a company’s performance with the performance of the best practitioners and adopt some of the best practices in their companies to improve their performance and compete successfully against the rivals.

To understand the concept of benchmarking very clearly, you must be open-minded and have a clear idea of TQM. Here, we can describe benchmarking both from conventional and Islamic perspectives.

Conventional Perspective

The evolution of benchmarking in literature and its practice in business organizations is not so old. Up to 1985, the use of benchmarking as an improvement tool was not widespread among business organizations. The Baldrige criteria framework (1987) has played a catalyst in using benchmarking.

According to the Baldrige criteria, when a company is going to apply for the award, it must finish the details about comparing its performance and the performance of its competitors and how it uses comparative data for further improvement.

By 1990, about half of the Fortune 500 companies had used benchmarking, even though there was no practice of benchmarking among them up to 1987.

Nowadays, thousands of small or large business organizations have found benchmarking a simple, systematic, and very effective tool to improve their performance.

Benchmarking considers the experience of others and uses it. The common-sense intention is to learn from others what they do right and then replicate it to avoid reinventing the wheel.

Benchmarking is a structured improvement tool that;

- measures a company’s performance, processes, and the quality of its products and services by comparing it with the performance of the best practitioners within or outside the industry,

- identifying the gaps between them,

- identifying the techniques used by the best practitioners and then implementing those techniques in their organization to improve the quality of their products,

- to improve customer satisfaction and

- To improve their business performance and compete successfully against their rivals.

In another way, we can say that benchmarking is a process used by companies to target key areas for improvement within their operations so that they can increase their productivity, competitiveness, and quality.

It involves comparing their financial and operating performances against a competitor’s performance or the performance of various internal departments against each other. Internal comparisons allow best practices within a company to be highlighted and ensure non-performing departments adopt the new standards.

The Malaysian Benchmarking Service of the National Productivity Corporation of Malaysia defines benchmarking as a systematic and continuous process of searching, learning, adapting, and implementing the best practices within the same organization or other organizations towards attaining superior performance.

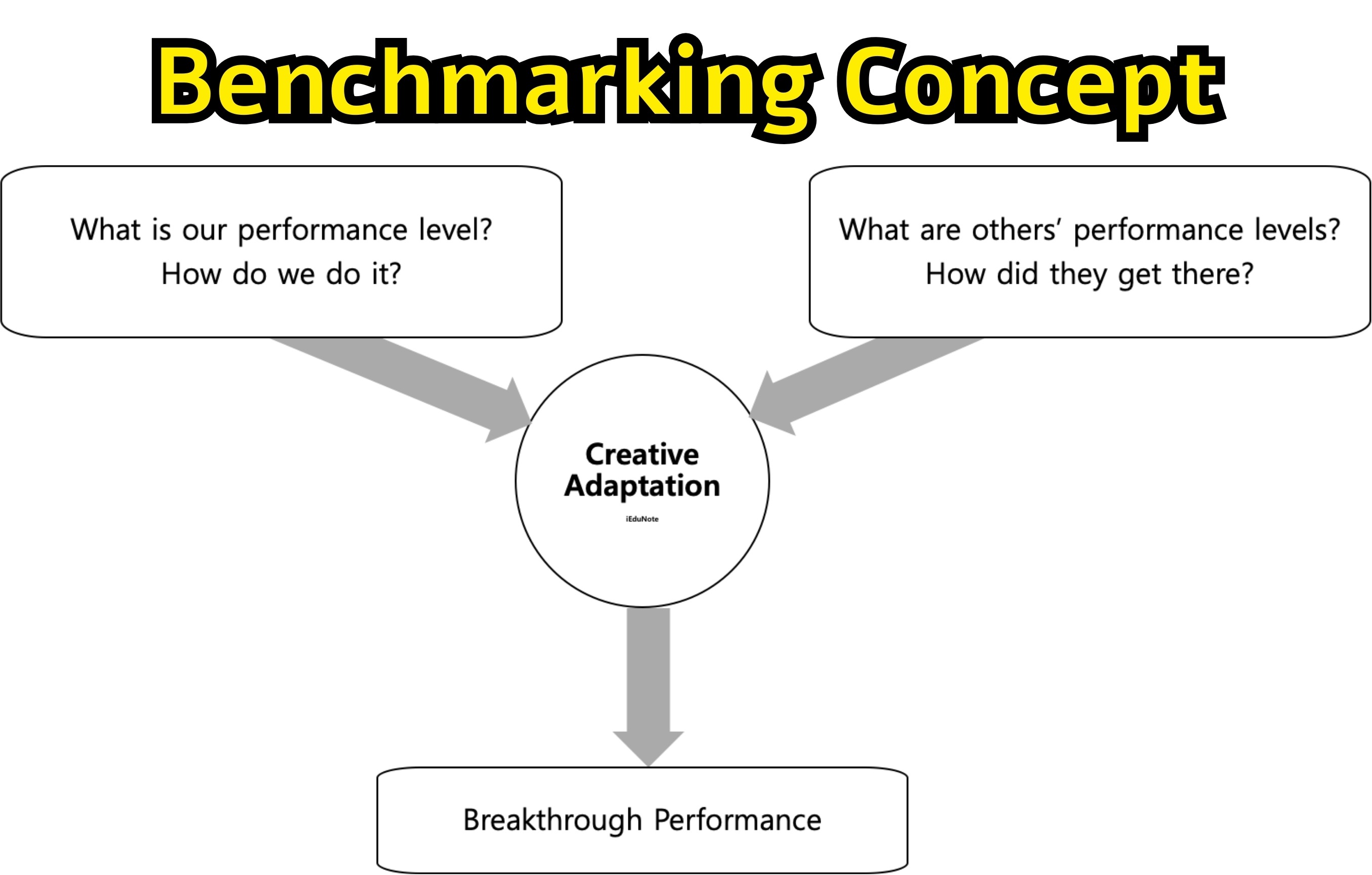

The figure above shows that benchmarking measures performance against that of best-in-class organizations, determines how the best-in-class achieve those performance levels, and uses the information as the basis for adaptive creativity and breakthrough performance.

Implicit in the definition of benchmarking are the following two key elements:

- Measuring performance requires some units of measure. These are called metrics and are usually expressed numerically. The numbers achieved by the best-in-class benchmark are the target. An organization seeking improvement then plots its performance against the target.

- Benchmarking requires that managers understand why their performance differs. Benchmarks must develop a thorough knowledge of their processes and the processes of the best-in-class organizations. Understanding the differences allows managers to organize their improvement efforts to meet the goal. Benchmarking is about setting goals and objectives and meeting them by improving processes.

Islamic Perspective of Benchmarking

Benchmarking is a very ancient concept in Islam. After creating human beings, Allah (SWT) asked them to be colored according to the color of Allah (SWT).

He sent many Prophets to this world, and they were models to be followed by all the people of these communities, with Prophet Muhammad (SAAS) being a model for all mankind. They asked people to follow their activities according to the wills of Allah so that others could become better human beings to Allah (SWT).

It indicates that in Islam, there is no prohibition of benchmarking; rather, it is encouraged. Even in Islam, it is one of the duties of the best-in-class practitioners that they will ask others to follow their good sides to do better.

As Allah (SWT) says, “There has certainly been for you in the Messenger of Allah (Muhammad SAW) an excellent pattern (an example to be followed) for anyone whose hope is in Allah and the Last Day and (who) remembers Allah often.”

In this verse, Allah (SWT) mentions that if people want to be good doers, then they need to have some standards, and those acceptable standards are present in the life of Prophet Muhammad (SAAS).

It is the duty of human beings to follow the guidance, principles, and practices of the Prophet (SAAS) in their life. The history is evidence of this process where a huge number of qualified sahabah were created who helped to spread the Islamic Era, which is known as benchmarking in TQM in the modern age.

And the Prophet (SAAS) said that he was sent as the rahmah (mercy) of Allah. He was sent as a teacher for mankind. In his life, all the good features were present to be followed by each individual and mankind at large.

Besides these, many examples are present in the life of the sahaba of the Prophet (SAAS), where they helped each other to do good deeds.

In the Qur’an, Allah says, “And cooperate with one another in virtue/righteousness and piety; but do not cooperate with one another in sin and transgression. And fear Allah; indeed, Allah is severe in penalty.” (Qur’an, 5: Al-Maidah 2).

It also teaches us that organizations must be practitioners of helping each other to provide better quality products and services to the customers. In this situation, organizations are liable to help others, and they should provide all sorts of support to less-quality provider organizations that need to be better-quality providers in the greater interest of society.

This is the benchmarking that is being practiced partially in modern organizations. It is notable here that it is not the duty of only the worst providers to practice benchmarking, but it is the duty of the best practitioners to support all sorts of guidance to the worst practitioners.

If all of the organizations follow this type of benchmarking, then one of the difficulties of traditional benchmarking, where the best-in-class organization is not willing to provide the hidden secrets to be the best, will be eliminated from the environment.

Why Benchmark?

There are ample reasons for practicing benchmarking in business organizations. Many studies have been conducted on the relationship between benchmarking and other business issues.

Among those studies, some findings are common. From those findings, some important reasons are mentioned below:

- Benchmarking determinants, namely ‘Emulate the best,’ ‘Measurement against the best,’ ‘Active benchmarking program,’ and ‘Continuous Measurement process,’ have positive and direct effects on product quality performance.

- Benchmarking in TQM has positive and direct effects on business performance through product quality performance.

- The Malaysian Benchmarking Index for the electronic and electrical industry is considered average, indicating moderate benchmarking involvement in TQM initiatives.

- Quality measurement, benchmarking, and employee focus have positive and direct as well as indirect effects on productivity.

- Benchmarking and supplier relations have significant and direct effects on profitability.

- There is a strong and positive relationship between benchmarking and customer satisfaction.

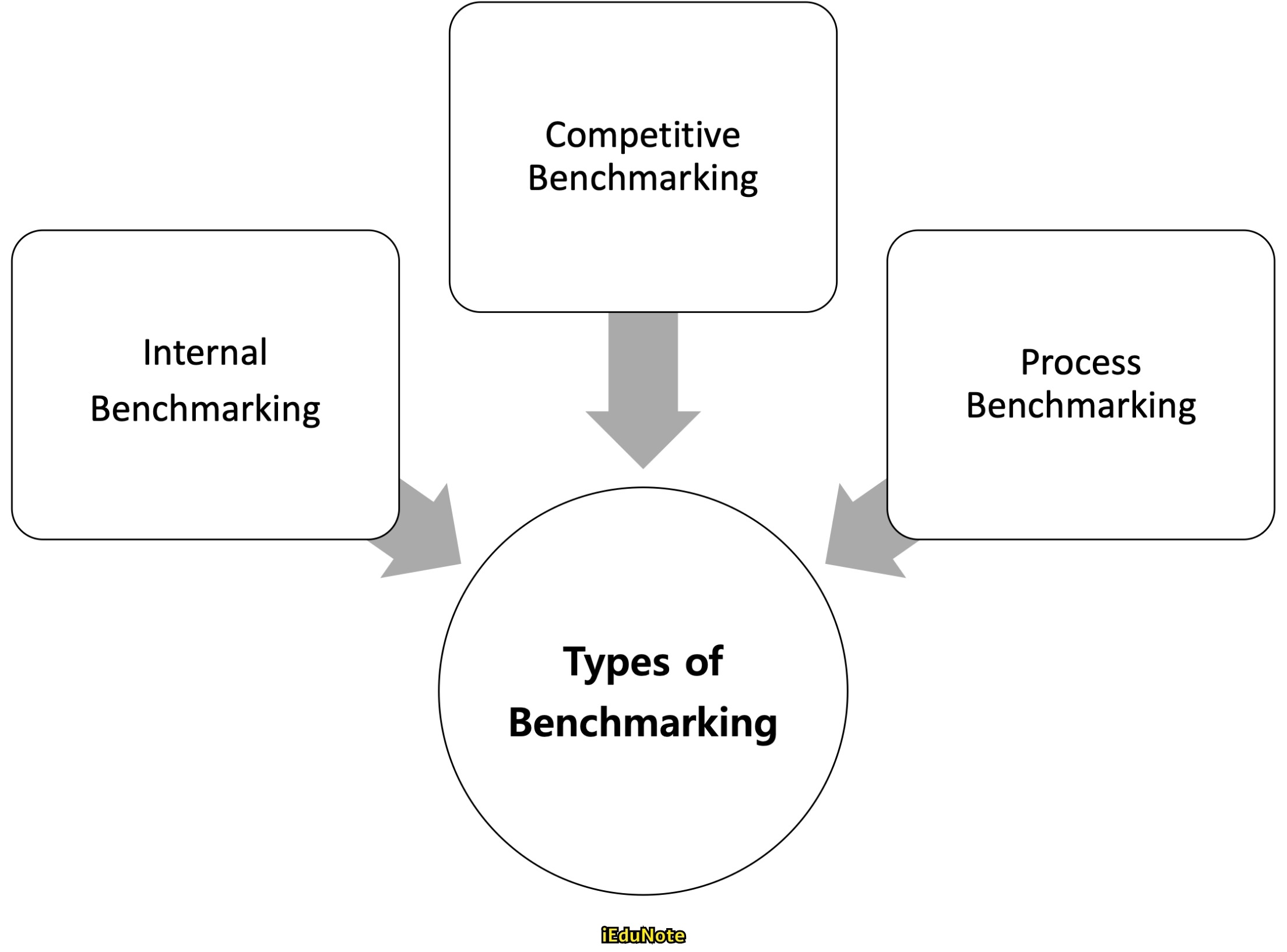

Types of Benchmarking

By explaining the definitions of benchmarking, we can easily get three types of benchmarking. These types are:

- Internal Benchmarking

- Competitive Benchmarking

- Process Benchmarking or Generic Benchmarking

Internal Benchmarking

When one department or unit of a company evaluates and compares its performance with that of another department or unit within the same company and implements the processes and approaches in its own department, then that is known as Internal Benchmarking.

Competitive Benchmarking

It is another commonly used type of benchmarking. In this case, a company selects the best-in-class performer in the same industry or from another industry, collects information about that organization, compares their performance with them, and then applies the strategies of the best-in-class performer in their own company.

All of these processes must be known to the best-in-class company, and with their full support, you can only practice their practices in your company. However, in most cases, the best practitioner may not be willing to support you.

Process Benchmarking

This is the highest level of benchmarking. In this benchmarking, a company usually takes the benchmark from another industry and tries to adapt only the process in their own organization that is used in the benchmark organization to produce products or to accomplish tasks.

In most cases, companies fail to understand the process and do not know how to adopt the new process of another industry in their company. But the companies who can do this may gain a very competitive advantage.

The advantage of this benchmarking is that you may get totally new ideas from a different industry that your competitor may not even know. This happened exactly with Toyota. One of Toyota’s executives observed that US consumers do not keep a lot of food in their homes.

When they need it, they go to the nearest supermarket and buy the food.

Having observed this, Toyota invented the lean production or just-in-time (JIT) production system in their operation line and inventory management system, which is now well known to other companies, and they are trying to implement these systems in their companies.

Phases of Benchmarking

Three phases are involved in benchmarking: preparation phase, execution phase, and post-execution phase.

Phase 1: Preparation Phase

In the preparation phase, several steps are to be followed. These are:

- Obtaining management commitment and approval for relevant expenses,

- Having the requisite number of manpower, and

- Making major changes in the organization after finding out the best practices from the best-in-class performers, etc.

The mandate of top management is absolutely essential before proceeding with benchmarking.

The baselining of the company’s own processes for a clear understanding of the processes by the managers themselves is necessary before beginning the benchmarking.

Unless the managers better understand own processes in terms of capability and flow diagrams (plus other aspects), nothing can be achieved out of benchmarking.

Documenting processes fully so that the partner companies can be provided with elaborate information about the company’s processes (whether weak or strong). The partners will not consider non-documented or weakly documented processes for obvious reasons.

Phase 2: Execution Phase

In the execution phase of benchmarking, at least five activities need to be performed by the company.

The company officials enter into agreements with the selected partners, gather information from the contracted partners, analyze the information after collection, prepare a plan of action regarding the adoption of the ‘best processes’, and implement the change.

The activities include:

- Entering into agreements with partners to identify the areas of benchmarking activities and deciding on the modus operandi of the benchmarking.

- Gathering data from the partner companies as per agreement through observing and documenting the partners’ processes.

- Analyzing the information and then comparing that information against the company s own processes so that gaps can be identified.

- Preparing action plans to close the gap or improve the partners’ performance in the process.

- Implementing change on the basis of data gathered from the partners may be time-consuming.

Phase 3: Post-execution Phase

The post-execution phase is entirely the management’s responsibility. This phase is involved with:

- Monitoring the performance of the processes that have been adopted out of benchmarking results and

- Updating the benchmarks on the basis of experience.

Benchmarking Processes

Organizations that benchmark and adapt new processes for achieving the best success according to their own needs and culture.

These processes may vary from organization to organization. For example, whereas AT&T follows a 12-step process, Xerox follows a 10-step process. These two are mentioned below:

Processes to benchmarking: AT&T’s 12-step Process vs Xerox’s 10-step Process

| AT&T’s 12-step Process | Xerox’s 10-step Process |

|---|---|

| Determine who the clients are- who will use the information to improve their processes. | Identify what is to be benchmarked. |

| Advance the clients from the literacy stage to the champion stage. | Identify comparative organizations. |

| Test the environment. Make sure the clients are and will follow through with, benchmarking findings. | Determine data collection method and collect data. |

| Determine urgency. Panic or disinterest indicates little chance for success. | Determine current performance gap- |

| Determine scope and type of benchmarking needed. | Project future performance levels. |

| Select and prepare the team. | Communicate benchmark findings and gain acceptance. |

| Overlay the benchmarking process onto the business planning process. | Establish functional goals. |

| Develop the benchmarking plan. | Develop action plans. |

| Analyze the data. | Implement specific actions and monitor progress. |

| Integrate the recommended actions. | Recalibrate benchmarks. |

| Take action. | |

| Continue improvement. |

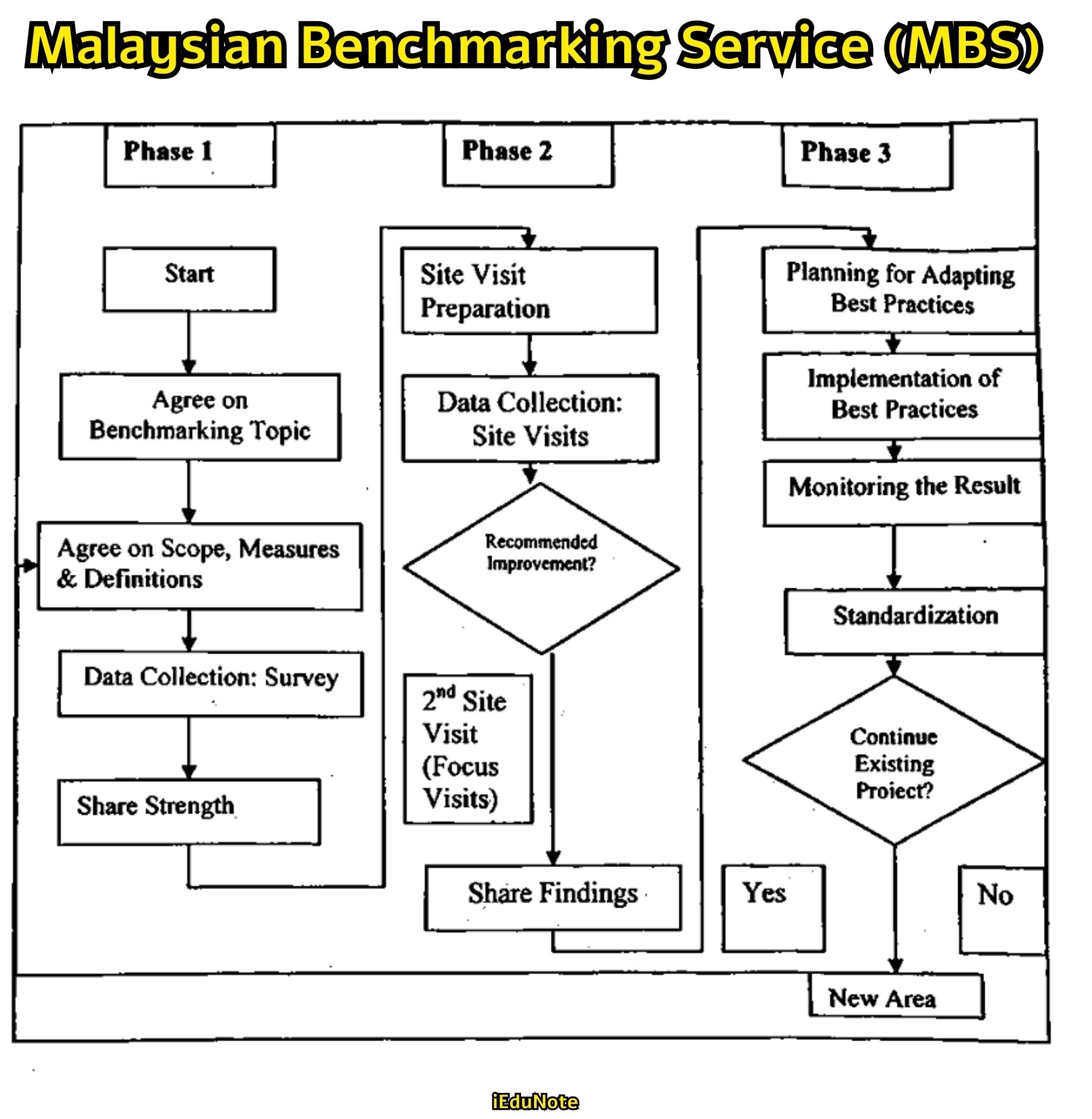

Malaysian Benchmarking Service (MBS) has provided a model named the MBS Benchmarking Model. This model consists of 14 steps arranged in 3 different phases. The first two phases are related to planning and analysis, and the third phase is related to the implementation of the best practices.

Benchmarking Methodology

Malaysian Benchmarking Service (MBS)

Although the number of steps may vary from organization to organization, some steps are very common for all organizations. These steps are as stated below:

- Make top management committed.

- Decide what to benchmark.

- Understand current performance.

- Plan.

- Study others.

- Learn from the data.

- Use the findings.

Making Top Management Committed

At the very beginning stage, top management of the company must agree with the benchmarking strategy of the organization. They should be committed to providing all sorts of support (financial, non-financial, logistics, and others) needed for benchmarking.

Top management’s endorsement of the best-in-class company’s mandate is absolutely essential before proceeding with benchmarking.

Unless the company’s own processes are better understood by the managers in terms of capability and flow diagrams (plus other aspects), nothing can happen out of benchmarking.

They should fully document processes so that partner companies can be provided with elaborate information about the company’s processes (whether weak or strong). Partners will not consider non-documented or weakly documented processes for obvious reasons.

Deciding What to Benchmark

After top management commitment, the second step is to decide what to benchmark

In this step, management has to decide whether to benchmark;

- the total management system,

- strategic management,

- total operations processes,

- human resource development process,

- management information system (MIS), or

- others that can greatly contribute to market and financial success.

Without making this decision, management can’t proceed with benchmarking.

Usually, processes that need to be changed should be selected. A benchmarking team may be built with people drawn from process operators, providers of inputs to the process, users of output from the process, and senior-level managers who will make decisions regarding benchmarking.

They will also have to search for and make a list of partners for benchmarking, and then the company should select those partners from the list who can be considered best-in-class.

Some questions that can be raised to decide high-impact areas to benchmark are:

- What are the mission and critical success factors?

- Which processes are causing the most trouble?

- Which processes contribute most to customer satisfaction, and which are not performing up to expectations?

- What are the competitive pressures impacting the organization the most?

- What processes or functions have the most potential for differentiating our organization from the competitor?

Understanding Current Performance

After deciding what to benchmark and from whom, the third step is to understand their current performance very clearly.

To compare practices with outside benchmarks, it is first necessary to thoroughly understand and document the current process.

Companies use several techniques to measure and understand performance, such as flow diagrams, cause-and-effect diagrams, and so on.

At the time of documenting the process, it is important to quantify it. Units of measure must be determined. These are the key metrics that will be compared during the benchmarking investigation.

For example, unit costs, hourly rates, asset measures, quality measures, etc. Also, the accounting information system should be easily understandable and able to present data without any misrepresentation.

Benchmarkers should take the time to determine what is and what is not included in accounting information.

Planning for Benchmarking

After understanding and documenting internal processes, the fourth step is to make decisions about how to conduct the whole study and implement the findings.

If not already decided, a benchmarking team should be chosen. The team should decide what type of benchmarking is to be performed, what type of data is to be collected, and what methods to use to collect and analyze data.

The planning process should result in a shortlist of possible benchmark partners. The scope of the study and the type of benchmarking may require examination of several organizations.

When a process is broken into sub-processes, it is found that a single organization is not best-in-class in all sub-processes. In these cases, a company needs to study multiple organizations to ensure the discovery of the best practitioners in all of the sub-processes.

Studying Others

Benchmarking studies usually are conducted to look for two types of information:

- description of how best-in-class processes are practiced and

- the measurable results of these practices.

Benchmarkers can use different types of sources to collect this information, like internal sources, the public domain, original research, etc., or most likely a combination of the sources.

At the time of collecting data, the organization must consider the cost and time involved in gathering data and the required quality and accuracy of that data.

Most organizations think of conducting original research through site visits and interviews. Some organizations feel that this type of research is more costly and time-consuming.

So, they prefer sources like internal and the public domain, which are easier and faster to collect data from. Which sources are to be used must be decided at the planning step.

Organizations usually follow three techniques for conducting original research: use of questionnaires, site visits, and focus groups. When data are desired from external organizations and when a third party is involved in collecting data, using questionnaires is the best way to ensure respondent anonymity and confidentiality.

Respondents can be surveyed by mail, by telephone, or in person. In addition, questionnaires can be developed as preparation for a site visit, as a checklist during a site visit, or as a follow-up device.

For any survey, careful design and interpretation of questionnaires are essential, especially when those are administered by mail or phone.

In the site visit approach, an organization can get the opportunity to see processes in action and for face-to-face contact with best-in-class operators.

It is so important to be properly prepared for the visit because employees of both the visiting and host organizations will invest time there. This face-to-face contact may establish a basis of mutual learning and information sharing as well as a strong link.

Learning from the Data

After collecting and studying necessary data, the sixth step is to compare the results of the study with the actual situation of the said organization and to identify the benchmark gaps. Identifiable benchmark gaps must be described in quantifiable units.

Processes have inputs, activities, and outputs. If both words and graphics are used to describe the process gaps, that would be superior.

This type of presentation would be easily understood and emulated. Describing best-in-class processes in appropriate detail is the primary way to determine why there is a gap and how to minimize it.

From the description, the size of the gap and the appropriate benchmark metrics and objectives should be easily understood.

Any summary measures are likely to be synthetic or derived rather than directly measured from external processes, and it is appropriate that metrics be expressed as ranges rather than a single number.

Because the benchmark sub-processes may not be in the same organization, and the nature and operations size and scale may not be the same for all the organizations.

After describing and quantifying the best-in-class processes, additional analysis is necessary to determine the root causes of the gaps.

The causes may be associated with the technologies used, the policies of the organization practiced, the operations systems, the marketing policies, the accounting information system, or the human beings working in the different sectors of the organization.

Though business practices are more or less general and may apply to many or all of the organization’s processes, their degree of quality and acceptance may vary. Business processes are ever-changing. So to cope with the changing situations, organizations need to go through better benchmarking studies.

Using the Findings

When the benchmarking study shows a negative gap in performance, the main objective is to minimize the gap through changing the process. Benchmarking may be valueless if the change does not bring any significant positive result.

To make the change effective, the findings must be communicated properly to the people in the organization. Top management and the process operator groups must be well-communicated and agreed upon to bring the required changes.

The findings must be translated into goals and objectives, and action plans must be developed to implement new processes. The new processes may affect upstream and downstream operations as well as suppliers and customers.

The changes have to be considered and incorporated into the strategic planning process. When recognition is gained, new goals and objectives are set based on the benchmark findings.

Exactly how this happens depends on the planning process of an individual organization.

The common steps for the development and execution of action plans are:

- Specify tasks.

- Sequence tasks.

- Determine resource needs.

- Establish a task schedule.

- Assign responsibility for each task.

- Describe expected results.

- Specify methods for monitoring results.

Goals and objectives should be consistent with the execution of the action plan so that the organization can execute the best processes.

The next step is to repeat the benchmarking process. Because benchmarking is a continuous improvement tool, it is not to be done once to create one permanent improvement. To pursue emerging new ideas, benchmarking must be used continuously.

TQM Exemplary Organizations

A lot of organizations have benefited from using the benchmarking tools. Some examples are stated below:

Seitz Corporation lost two-thirds of its workforce and saw annual sales drop from $12 million to $5 million in the mid-1980s. Then, the company used benchmarking.

After six years of using benchmarking, the sales volume rose to $21 million. In 1992, the company won the state Blue Chip Enterprise Initiative Award as ‘the best example of a small business that effectively used resources to overcome adversity and emerge stronger.’

Motorola’s benchmarking partners are Wall Mart, Benetton, and Domino’s Pizza. The benchmarking practice resulted in a 70% improvement in both quality and cycle time. The time it actually takes to process a customer’s order was reduced from 15 days to 3 hours only.

Motorola emphasizes benchmarking human beings. It encourages its employees to ask the question, ‘who is the best person in my own field and how might I use some of his/her techniques and characteristics to improve my own performance in order to be the best in my class?’

Karlee is a contract manufacturer of precision sheet metal and machine components for customers in the telecommunications, semiconductor, and medical equipment industries.

It started its operations in 1974 as a one-man garage-based machine shop. Its work ranges from initial design and prototyping to painting and assembling to integration of cabling and power elements.

To guide improvements in manufacturing and service performance, the company makes extensive use of benchmarking studies. Between 1996 and 2000, production volumes tripled. Still, assembly lead times were trimmed from weeks to two or three days and, in some cases, to a few hours only.

The American Productivity and Quality Center (APQC) is probably America’s major benchmarking organization. It was founded in 1997 by C. Jackson Grayson as a non-profit corporation to help organizations of all kinds improve productivity and quality.

It does that through training programs, information services, policy development, research, publications, and consulting.

It was one of the first organizations to start what is now the Baldrige Award, which it co-administrated for three years. The most prominent concept of the APQC is its International Benchmarking Clearinghouse (IBC), which was established in 1992.

Benefits of Benchmarking

From the past records, achievements of benchmarking practitioners, and some case studies, we can draw some benefits of benchmarking. These are pointed out below:

- It ensures that best practices are identified, which, in turn, ensures that appropriate improvement targets are set.

- It enables a deep understanding of the organization’s processes.

- It helps overcome disbelief in outside practices and convinces an organization that it can improve on them.

- It counters reluctance to try something different and stimulates innovations and breakthroughs.

- It helps identify new technologies that may have started in other industries, e.g., bar-coding.

- It redirects the focus of an organization, helping it to turn outwards and thus see ‘outside the box’.

- It is a practical tool for continuous improvement.

- Benchmarking allows organizations to set realistic, rigorous new performance targets, and this process helps convince people of the credibility of these targets.

- This tends to overcome the “not invented here” syndrome and the “we’re different” justification for the status quo.

- Benchmarking allows the organization to define specific gaps in performance and to select, the processes to improve.

- It provides a vehicle whereby products and services are redesigned to achieve outcomes that meet or exceed customer expectations.

- The gaps in performance that are discovered can provide objectives and action plans for improvement at all levels of the organization and promote improved performance for individual and group participants.

- Benchmarking provides a basis for training. Employees begin to see the gap between what they are doing and what best-in-class are doing.

- Closing the gap points out the need for personnel to be involved in problem-solving and process improvement techniques.

- Moreover, the synergy between organization activities is improved through cross-functional cooperation.

Pitfalls of Benchmarking

Though benchmarking practices help organizations improve, there are some criticisms, too. Critics say that these are the pitfalls of benchmarking.

- Benchmarking is the idea of copying others. Without innovative activities, it is very difficult for an organization to improve and even to survive.

- Benchmarking is not a panacea. It is not a strategy nor a philosophy at all. It is just an improvement tool only. Without using it correctly, a company can not benefit from it.

- Benchmarking is not a substitute for innovation; it is a source of ideas from outside organizations.

- Most of the time a best practitioner organization does not agree to help others to benchmark.